Quality control

We understand you’re flying potentially millions of dollars worth of equipment and payload, which is why quality and consistency are the number one priority for us. Learn the process behind our quality assurance, and the additional testing available to get your platform certified.

Balancing

Propeller balance is crucial. This is why balance control goes through three phases: while manufacturing, during quality control, and finally before shipping.

Propeller structural test

Each propeller undergoes uncompromising weight tests and are bent by a force much higher than during flight. Through this, we ensure the propeller is well-constructed and all the inner layers are connected together.

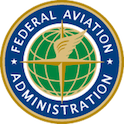

Visual test

When performing visual tests, we make sure the leading edges have the right shape, there are no bubbles in the epoxy, drilling is right and all the informational marks on the propeller are placed correctly.

Aditional testing

We can perform tests to certify your platform. Among others: complying with FAR part 35, airworthiness standard: Propellers.

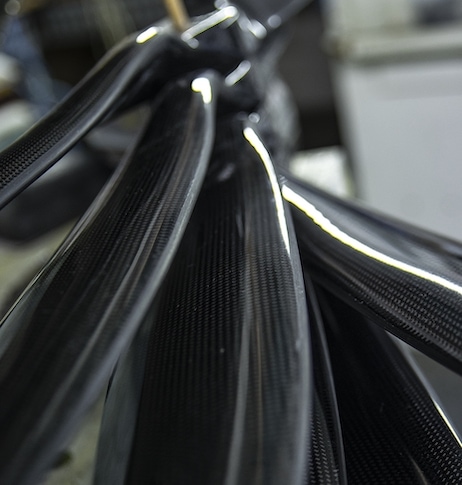

Static testing rig

We have in-house testing rigs which measure propeller thrust from 50 grams up to 300kg. The report includes values of thrust, torque, rpm, voltage, current, mechanical and electrical power, efficiency of propeller/motor/setup and ambient conditions.

Additional testing

Let's perform tests together with our partners at certified EASA and FAA aviation center. Endurance, salty environment, strength tests, speed camera tests, wind tunnel tests and more.