Process

We know that every business cooperation needs an individual approach. As we are manufacturers of our own propellers, we are able to adjust any part of the process for our clients.

Pre-sales

- 1

Contact us to schedule a meeting. In order to cooperate, we need to know your platform.

- 2

Sign an NDA.

- 3

Provide more details by telling us about your aircraft/motor.

- 4

Based on the info provided, we'll give you a quote and timeline for future cooperation.

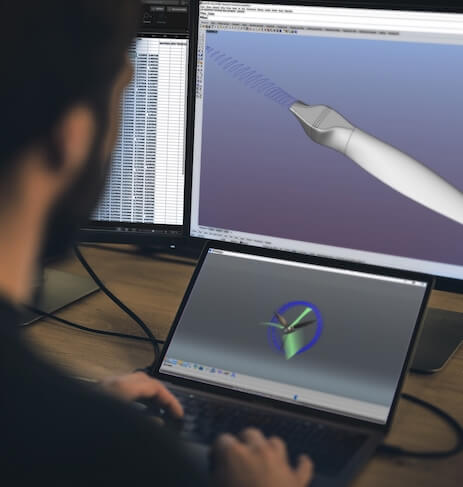

Designing and consultancy

- 5

Simulation of a propeller.

- 6

We help you determine the right propeller motor ESC combination.

- 7

We help you test different setups (both statistically and dynamically using a wind tunnel) already existing on the market to gather more data and help you even more.

- 8

Create a 3D file of a propeller.

Design in detail

Tooling and Prototyping

- 9

Some propeller molds can be made out of sica block. We call them internally prototyping propellers.

- 10

We'll figure out the structure—different layers of carbon fibre, central piece, inserts etc,—of the propeller.

- 11

Try the prototype out on your aircraft to see how it goes.

Propeller production on scale

- 12

Turning a prototyping mold into a production one.

- 13

Let's agree on the final setup—what the final drilling and carbon layer will be.

- 14

We find out what are the limitations of a mass production.

Quality assurance and testing

- 15

What quality assurance do you need, apart from our standard ones?

- 16

Need any certificates? We'll help you get them.